Description

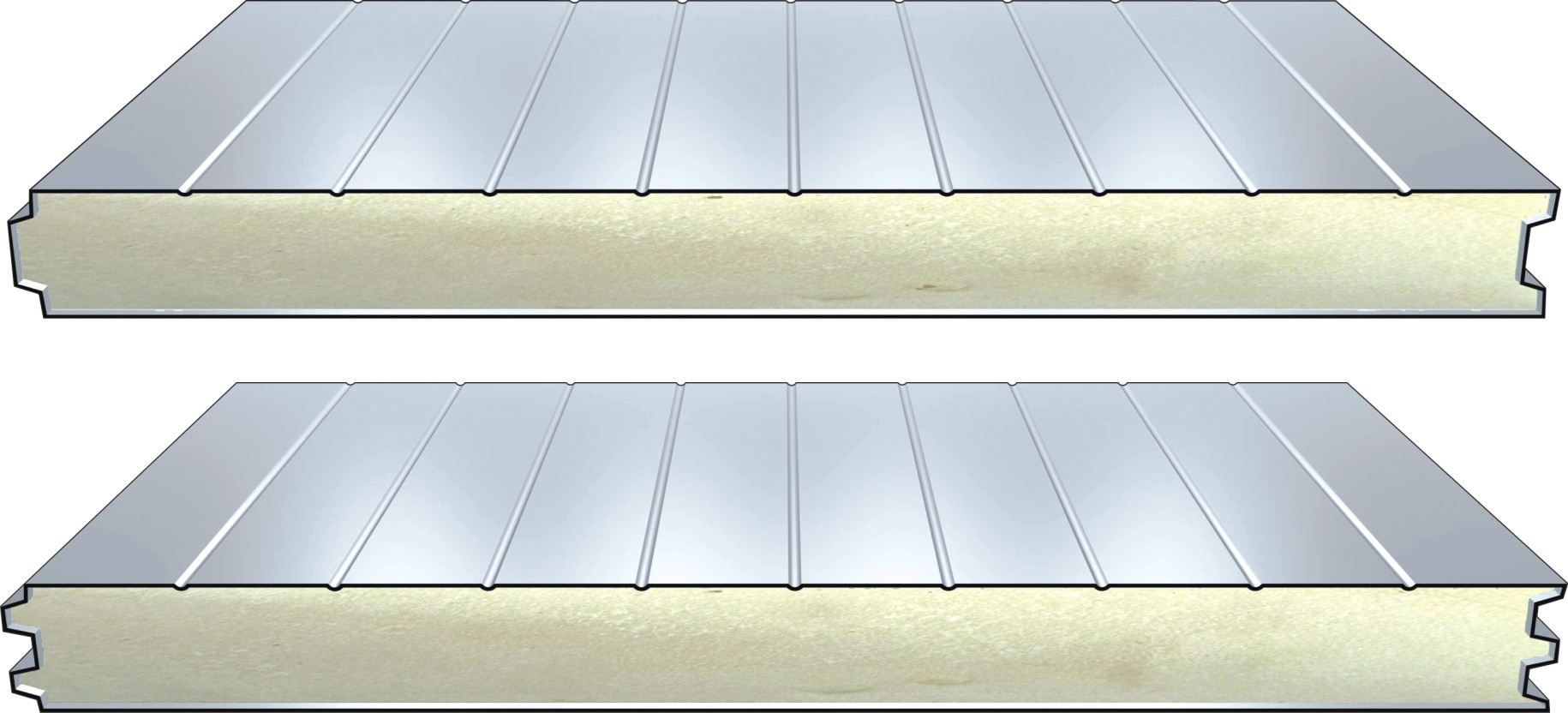

SD3232 formulated polyol is a kind of spraying polyurethane rigid foam system designed with HCFC-141B as blowing agent. It is specially used for the color steel sandwich panel. It contains all the raw materials and auxiliaries necessary for the production of rigid polyurethane foam including the blowing agent. It has the characteristics as following:

n It has strong adhesive force and not to take off.

n The light weight, high strength and good supporting performance

n The low thermal conductivity, low water absorption, good dimensional stability and good flame retardant.

n The long service life, convenient and fast construction

Applications

This product is suitable used for continuous production line of color steel sandwich panel, it is can be used for the products of thermal insulation workshop wall, roof boarding, combination cold storage, door plank and other products.

Characteristics

① Basic Parameters

|

Characteristics |

Index |

Unit |

Testing Method |

|

|

Density (25°C) |

1.2±0.1 |

g/cm3 |

GB/T6343-2009 |

|

|

Viscosity (25°C) |

200-500 |

mPa.s |

GB/T12008.7-2010 |

② Reaction Time Parameter and Product Properties

SD3232 type polyol blend system will use continuous color steel line foaming machine, here with the laboratory parameter for reference, actual value will be different depending on the construction conditions. Component A (PM400) provided by Wanhua company.

Reaction index(Laboratory free foaming, mixing speed 3500r/min)

|

Environment temperature (℃) |

22±3 |

|

Component A temperature (℃) |

22±1 |

|

Component B temperature (℃) |

22±1 |

|

Mix Ratio/(A:B) |

According to the inquiry of the customer |

|

|

|

|

Mixing Time /(s) |

8"00 |

|

Cream Time/(s) |

10"00-20"00 |

|

Gel Time/(s) |

50"00-90"00 |

|

Tack Free Time/(s) |

100"00-200"00 |

|

Free Rise Density/(kg/m3) |

36±2 |

Remark: Above data is obtained by the lab testing, actual data at customer side may be different because of test machine and condition, etc. And all the data listed of our products will have no any legal force.

③ Foam Specification

|

Core Density /(kg∕m³) |

≥30 |

|

Compressive Strength /(mPa) |

≥0.15 |

|

Thermal Conductivity /(w/m.k) |

≤0.024 |

|

Oxygen Index /(%) |

According to the inquiry of the customer |

|

Dimensional Stability( -25℃,48h )/(%) |

≤1.5 |

|

water Absorption /(%) |

≤3.0 |

Packaging:

The material is normally supplied in iron pail with Zinc coating in standard container, 220kgs/drum.

Storage Recommendations:

The SD3232 is hygroscopic and containers must be kept sealed tightly to prevent absorption of moisture, which can adversely affect processing. During the transportation, it should avoid serious shake and strong sunlight. It should be stored in ventilated place, avoiding light, water and fire. Recommended storage temperature is 10~25℃.